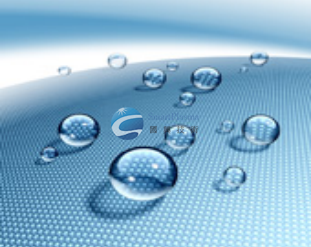

1. Textile industry Plasma pretreatment technology can significantly improve the wettability of fibers and yarns, even for dyes that do not contain solvents. Obtain a firm and long-lasting dyeing effect. The surface of the fabric can obtain hydrophilic, hydrophobic and anti-fouling coatings.

2. Examples of products

1. Yarn

Purpose: To increase the hydrophilicity of the yarn, and the pretreatment before dyeing can improve the color fastness.

2. Fabrics and non-woven fabrics

Uses: Pretreatment before dyeing and finishing, to improve the wettability combined with water-based treatment materials.

3. Special coated fabric

Uses: Pretreatment of functional coatings.

Description: (1) Fiber and yarn manufacturing technology is the first step in the textile production chain. Modern textiles need long-lasting and stable colorfastness Solidity, while reducing the use of solvents. After plasma treatment of fibers and yarns, its wettability is significantly increased, even Solvent-free dyes can also adhere firmly and lastingly. (2) Plasma treatment technology can realize the hydrophilicity of fabrics, and can be used in subsequent processes (such as dyeing, printing or textiles). Finishing) to improve the wettability combined with water-based treatment materials. (3) By creating new functional surfaces, such as self-cleaning coatings, bioactive surfaces and flame-retardant properties, fabrics can obtain Brand new quality. This will promote the birth of many new applications. In many cases, it is even possible to substitute low-cost materials for transmission System materials. Textiles with functional coatings, for sports and leisure clothing, protective clothing, medical or sanitary products, or textiles It is necessary for the production of structural membranes.

Three, process flow Cleaning→plasma surface treatment (cleaning, activation and roughening)→printing and dyeing, coloring, coating

4. Craft value: (1) Dry process to reduce sewage discharge; (2) Improve the process, improve product quality and yield; (3) The surface can achieve hydrophilicity, or hydrophobicity and anti-staining properties; (4) Make the production process green and environmentally friendly, and significantly reduce costs.

Consult now