Application of plasma equipment in biomedical industry: 1. Biomedical The meaning of medical biomaterials refers to natural or man-made materials used to replace and repair living tissues. The biocompatibility of the material means that the material will not cause blood coagulation, toxicity, allergy, carcinogenesis, immune response, etc. after being implanted in the organism, and at the same time coordinate with the organism and perform the expected function. How to improve the biocompatibility of medical biomaterials and make them suitable for clinical transplantation surgery and scientific research has always been the goal pursued by biologists and materials scientists. Low-temperature plasma technology includes etching, deposition, polymerization, surface cleaning and disinfection, etc. It can coat, polymerize, modify, and modify the surface of materials. This can improve the hydrophilicity, air permeability, and blood solubility of biological materials, so that biomedical materials such as artificial blood vessels and hemodialysis membranes can be widely used.

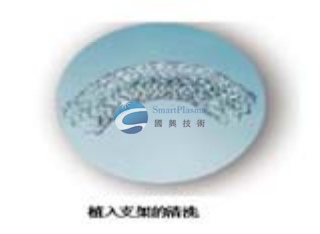

1. Medical equipment

(1) Purpose: Use the cleaning, activation and etching effects of plasma to increase the biocompatibility of medical devices in vivo and in vitro; it can achieve effective adhesion of different types of soft/hard material combinations, which is beneficial to coating. ① Plasma cleaning of stents and implanters moved into the human body; ② Activation treatment of the electrode carbon film of the biosensor (glucose meter) before the functional coating of the medical equipment; ③ Hydrophilic coatings for diagnostic equipment, low-friction coatings for medical equipment, and bioidentical coatings for implantable equipment that prevent cell growth. (2) Description: ① The production process of medical devices needs to adopt the highest possible standard, which is far higher than the requirements for any other industry. The surface of the object must not only be clean, but must be absolutely dust-free or sterile. In addition, the pretreatment process used in pharmaceutical technology must be very reliable and can be accurately reproduced. ② Plasma pretreatment technology has been widely used in the field of medical equipment to improve the adhesion of printing inks. With plasma technology, the application in this field has been greatly advanced. ③Using the plasma process, different types of soft/hard material combinations can be effectively bonded, the final processing of the membrane (filter material), and the plasma functional modification of the plastic surface can be achieved. (3) Process flow: Cleaning→plasma surface treatment (cleaning, activation and etching)→printing, bonding (4) Process value: ①The dry physical treatment process without chemicals is simple and easy; ②Reliable and reproducible process parameters; ③As the plasma sterilization is adopted, this process can ensure sterility.

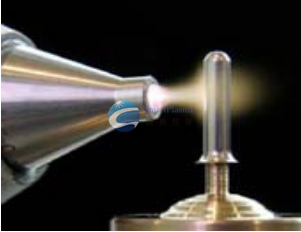

2. Plasma drugs

(1) Purpose: There is a synergistic relationship between sterilization and wound healing through the use of plasma (plasma disinfection). (2) Description: "Plasma drugs" refers to the use of plasma to directly treat human cells. It is called "plasma sterilization". Plasma spray guns are very effective for surface treatment in continuous operation. Since the plasma is potentialless, it is theoretically suitable for Treat human skin.

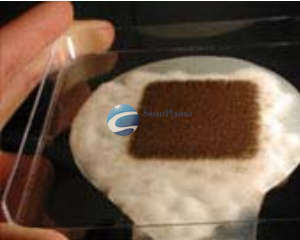

3. Plasma disinfection

(1) Purpose Microbial growth without plasma treatment Plasma treatment can kill microorganisms (2) Description: ① Microorganisms in nature, such as fungi and bacteria, are extremely important for the material cycle of nature and the maintenance of ecosystems. Microorganisms are even used in the pharmaceutical and food industries to produce specific active ingredients. On the other hand, bacteria and fungi can cause diseases, and toxic reactions may follow. In industrial production, even the slightest pollution can cause major problems, even up to the point of causing product deterioration or destroying the entire system. ②Using vacuum or even atmospheric pressure plasma technology as a very effective surface disinfection (plasma disinfection) method. The pulsed plasma trigger of the plasma process combined with special process gases is particularly suitable for safe surface disinfection. Since the plasma is not charged, a simple and easy-to-control independent or online process mode can be realized, while also having 100% process reproducibility.

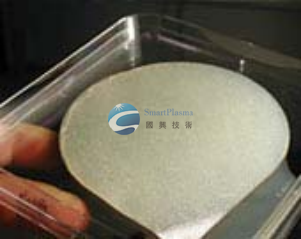

4. Medical consumables

use: (1) Plasma cleaning of contact lenses, plasma cleaning of medical catheters; (2) Activation treatment of urinary catheter before bonding, printing and coating; (3) Activation treatment of the needle before bonding; (4) Activation treatment of cell culture dishes and other diagnostic equipment to improve their infiltration (5) The polystyrene enzyme label plate is plasma grafted to introduce active functional groups such as aldehyde groups, amino groups, and epoxy groups to secure the enzyme Fix it firmly on the carrier to improve the fixation of the enzyme; (6) Hydrophilic coating of medical tubes and drug delivery equipment; (7) The hydrophilic coating of the non-woven fabric on the blood filter; (8) Non-woven oil-transporting coating on masks and air filters; (9) Functional coating for medical textiles; (10) Functional coating for contact lenses.

Tags:

Consult now